Proper pipe sizing is crucial to mitigate sediment buildup in water flow systems. Factors like water type, expected flow rates, and contaminants impact dynamics, affecting friction, flow speed, and pressure drops. Sudden changes in pipe diameter can cause turbulence, exacerbating sediment accumulation. Regular maintenance checks and proactive management ensure smooth flow, prevent blockages, maintain system integrity, and avoid costly repairs by addressing buildup risks early.

Ensuring optimal pipe sizing is paramount for efficient water flow, preventing costly clogs and minimizing sediment buildup. This article delves into the dynamics of water flow, exploring factors influencing pipe dimensions. By understanding these variables, from fluid velocity to pressure drops, you can optimize piping systems. We examine strategies to mitigate sediment accumulation risks, ensuring smooth operations and extending infrastructure lifespan. Learn how to navigate these considerations for effective management in various applications.

Understanding Water Flow Dynamics

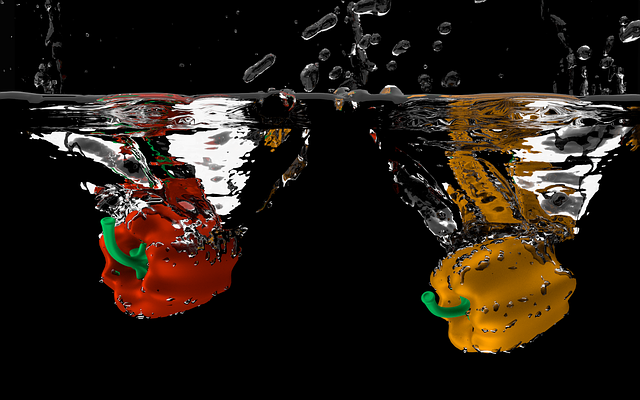

Understanding water flow dynamics is crucial for ensuring proper pipe sizing. When water flows through pipes, various factors influence its velocity and pressure. The presence of sediment buildup can significantly impact flow rates by increasing friction between the water and the pipe walls. This not only reduces water speed but also increases pressure drops along the pipeline, affecting overall system efficiency.

Additionally, abrupt changes in pipe diameter or configuration can cause turbulence, further exacerbating sediment buildup. To mitigate these issues, engineers must consider the type of water (e.g., raw vs. treated), expected flow rates, and potential contaminants present. Proper pipe sizing accounts for these dynamics, ensuring smooth water flow with minimal obstructions, thus maintaining system integrity and performance over time.

Factors Affecting Pipe Sizing

Several factors influence pipe sizing for optimal water flow, and understanding these is crucial for effective plumbing design. One significant consideration is the potential for sediment buildup within the pipes. As water flows through a system, it can carry dissolved solids, sand, or other debris that may accumulate over time, leading to reduced water velocity and increased pressure drops. This is especially pertinent in areas prone to high mineral content in water sources or regions with poor water quality.

Additionally, pipe size should account for the type of water being transported, its temperature, and the desired flow rate. Warmer water tends to flow faster and may require larger pipes to maintain efficient velocity levels. The presence of air bubbles or gases can also impact flow dynamics, necessitating careful sizing to prevent turbulence and pressure loss. Moreover, the overall length and elevation changes in a plumbing system play a role; longer runs or significant vertical drops might demand larger pipes to minimize pressure losses.

Mitigating Sediment Buildup Risks

Proper pipe sizing is essential to mitigating risks associated with sediment buildup in water flow systems. As water travels through pipes, it can pick up and transport sediments, debris, and even smaller particles. If pipe diameters are not correctly sized, this can lead to a buildup of these substances over time, causing clogs and reducing the efficiency of the system. For instance, too small a pipe for the given flow rate can result in increased velocity, leading to erosion and the eventual dislodging of sediment, which can then cause blockages downstream. Conversely, oversized pipes may allow sediments to settle, creating deposits that reduce the effective cross-sectional area of the pipe, leading to similar issues over time.

Regular maintenance checks are crucial for early detection of sediment buildup risks. These inspections should include monitoring pipe diameters and flow rates, as well as assessing the type and quantity of sediments present. By addressing these factors proactively, system managers can ensure smooth water flow, prevent costly repairs, and maintain the integrity of their piping infrastructure.